Survey and setting out, as a core preparatory process before road marking, plays a decisive role in the line shape. Traditional manual lofting requires the cooperation of multiple people, and the work efficiency is low, and there are also problems of inaccurate lofting.

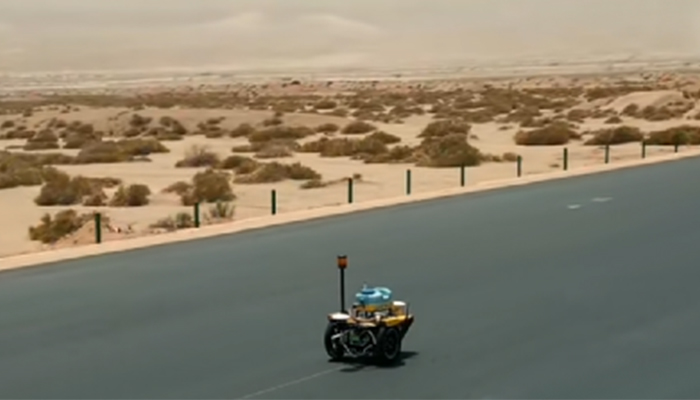

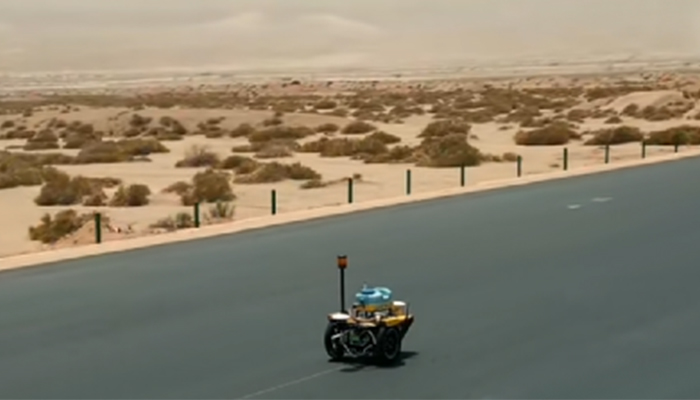

But now, with our intelligent base line marking robots, none of this is a problem. This intelligent marking robot adopts high-precision positioning technology, users only need to remotely set and monitor through the cloud platform, the robot can automatically complete the lofting task. The operation is simple and convenient, which effectively solves the problems of insufficient manpower, high cost and inaccurate lofting, and shows excellent performance without fatigue and interruption in continuous operation. No matter how big the engineering challenge, it's easy to tackle.

| Precision |

±1cm |

| Speed |

0.7m/s(2.5km/h) |

| Marking Line Type |

straight lines, curves, dashed lines, solid lines, complex graphics such as arrows, text, etc |

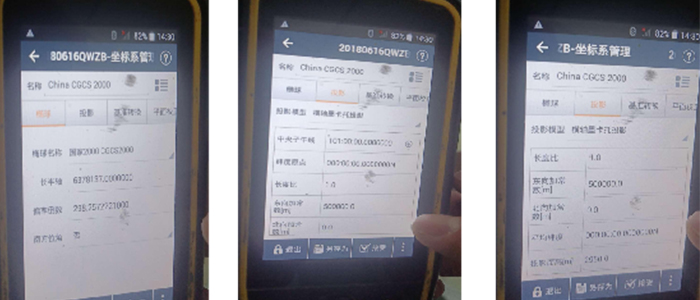

| Locating Method |

GNSS, RTK |

| Max Remote Control Distance |

100m |

| Emergency Braking Mode |

Remote control or body emergency brake button |

| Battery Type |

Li-battery |

| Max Battery Life |

8H |

| Chassis Type |

Differential wheels |

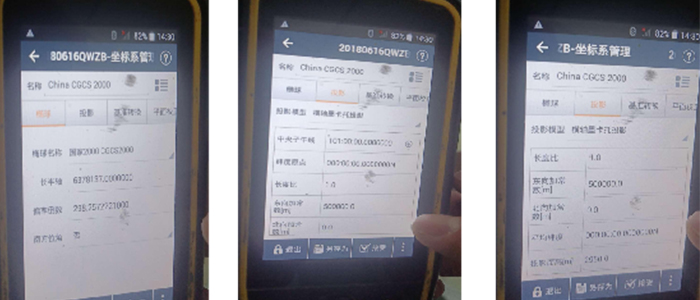

1. On-site survey: ensure that the site is open and the network signal is good;

2. Obtain coordinates: manually collect on-site information according to the design file;

3. Data sharing: the technology center obtains data and processes it;

4. Remote transmission: remotely transmit the processed application data to the lofting equipment;

5. Start lofting: connect the device through the mobile phone APP or remotely control the lofting task.